Opening a toolbox for the first time can feel overwhelming. You see a jumble of steel tools that all look slightly different, and you have no idea where to start. This uncertainty can stop you from trying even the simplest car maintenance tasks. But what if you could look at those tools with confidence, knowing exactly which one to grab for the job?

My name is Sharmin, and for the past five years, I’ve been working hands-on with automotive tools every single day. My work involves guiding new car owners, just like you, through the process of building their skills and confidence. I’ve seen firsthand how understanding the right wrench can transform a frustrating afternoon into a successful and satisfying repair. This guide is built on that experience. We will break down the essential wrenches you need to know, explaining what they do, when to use them, and why choosing the right one is so important.

Why the Right Wrench Matters for Your Car

Using the wrong tool on your vehicle is more than just inefficient; it can be damaging. A wrench that doesn’t fit snugly can round off the edges of a bolt head, making it nearly impossible to remove. This turns a simple task, like changing your battery, into a costly problem. Worse, a slipping wrench can lead to scraped knuckles or more serious injuries.

Before we dive into the specific types, it’s crucial to understand the two measurement systems you’ll encounter. Your car’s nuts and bolts are made to one of two standards: Metric or SAE (Society of Automotive Engineers), also known as Imperial or standard.

| Measurement System | Used On | Common Examples |

| Metric | Most modern cars, especially those from European and Asian manufacturers. | 8mm, 10mm, 12mm, 14mm, 17mm |

| SAE (Imperial) | Many older American-made cars and some specific parts on modern domestic vehicles. | 3/8″, 1/2″, 9/16″, 3/4″ |

Using a metric wrench on an SAE bolt (or vice versa) is a common mistake that almost guarantees a stripped fastener. Always make sure your tool is the perfect fit before applying force.

The Foundation of Your Toolkit: The Combination Wrench

The combination wrench is likely the most recognizable tool in any set. It’s a single piece of metal with a different style of wrench on each end, designed to handle the same size nut or bolt. This simple but brilliant design makes it incredibly versatile.

What is a Combination Wrench?

Think of it as two tools in one.

- The Open End: This U-shaped end is designed to slide onto a nut or bolt from the side. It’s perfect for situations where you can’t place a tool directly over the top of the fastener, like on a fluid line nut. It allows for quick work, as you can easily place it on and take it off.

- The Box End: This enclosed end surrounds the nut or bolt head completely. It typically has 6 or 12 points of contact inside. The box end provides a much more secure grip, significantly reducing the chance of slipping and rounding the fastener. This is the end you should use to break a bolt loose or for final tightening.

Common Automotive Uses

The combination wrench is your go-to tool for a wide range of basic tasks. I often reach for one when dealing with battery terminals, which are usually a 10mm or 13mm nut. They are also perfect for loosening or tightening bolts on engine accessories like the alternator or power steering pump, where you might have just enough room to swing a wrench.

I once helped a friend who was struggling to tighten a new battery terminal. He was using a pair of pliers, and the soft lead of the terminal was getting mangled. I handed him a 10mm combination wrench. Using the box end, he was able to apply the proper force securely, solving the problem in seconds and ensuring his car would start reliably.

Pros and Cons of Combination Wrenches

| Pros | Cons |

| Versatile: Two tools in one handle a variety of situations. | Slow: Can be time-consuming for long bolts as you must reset the wrench after each turn. |

| Simple and Reliable: No moving parts to break or wear out. | Limited Access: In very tight spaces, you may not have room to swing the wrench. |

| Excellent Leverage: Their length provides good mechanical advantage for stubborn bolts. | Fixed Size: You need a different wrench for every single size of nut and bolt. |

| Affordable: A complete set is one of the most cost-effective tool purchases you can make. |

Workhorse of Car Repair: The Socket Wrench and Ratchet

If the combination wrench is the foundation, the socket wrench is the engine of your toolbox. This system is responsible for the vast majority of work done on a modern vehicle. It is a three-part system consisting of a ratchet, sockets, and often, extensions. This modular design makes it incredibly fast and adaptable.

Understanding the Components

The magic of the socket set comes from how its parts work together.

- The Ratchet: This is the handle. Inside its head is a gear mechanism that allows you to tighten or loosen a bolt with a back-and-forth motion, without ever removing the tool from the fastener. A small lever on the back of the head switches the direction from tighten to loosen. Ratchets come in different “drive” sizes, which refers to the size of the square post that the socket attaches to.

- The Sockets: These are the small, cup-like attachments that fit over the nuts and bolts. They come in a massive array of sizes in both Metric and SAE. You’ll also see 6-point and 12-point versions. For beginners, I always recommend 6-point sockets. They grip the flat sides of a bolt head, providing maximum contact and minimizing the risk of stripping. 12-point sockets can work at more angles but are more prone to slipping on stubborn bolts.

- Extensions and Adapters: These are simple bars that fit between the ratchet and the socket. Their job is to help you reach bolts that are buried deep in the engine bay or in other awkward locations.

Real-World Car Maintenance Examples

The socket set is essential for countless jobs. When you change your oil, you’ll use a socket and ratchet to remove the oil drain plug. Changing your wheels requires a large socket (a “lug nut socket”) and a long-handled ratchet or breaker bar for leverage. Even a task like replacing spark plugs requires a special deep socket with a rubber insert to protect the porcelain insulator.

Key Considerations for Drive Sizes

The drive size of your ratchet and sockets determines how much force they can handle. Choosing the right one makes the job easier and prevents you from breaking your tools.

| Drive Size | Common Applications | Details |

| 1/4-inch | Interior trim, small sensors, plastic engine covers. | Best for low-torque, delicate jobs where precision is more important than power. |

| 3/8-inch | General-purpose repairs: brackets, oil changes, brake calipers, most engine bolts. | This is the most versatile and essential size for any car owner. If you only buy one set, make it a 3/8-inch drive. |

| 1/2-inch | Lug nuts, suspension components, crankshaft bolts, axle nuts. | Used for high-torque applications where you need maximum strength and leverage. |

The Most Misunderstood Tool: The Adjustable Wrench

Often called by the brand name Crescent wrench, the adjustable wrench is a tool of convenience. It has one fixed jaw and one movable jaw that is adjusted with a worm screw. In theory, this means one wrench can fit a multitude of sizes. However, this flexibility comes with a significant drawback.

When to Use It (and When Not To)

Because the movable jaw is never as secure as a fixed-size wrench, it is far more likely to slip under high force. This makes the adjustable wrench notorious for rounding off bolt heads. For this reason, you should never use an adjustable wrench for high-torque jobs like loosening a stuck bolt or for critical final tightening.

So, when is it useful? It’s a decent backup for odd-sized fasteners you don’t have a specific wrench for, or for holding the nut on the back of a bolt while you tighten the other side with a proper wrench. The key to using it safely is to ensure the jaws are tightened snugly against the fastener and to always pull the handle toward the fixed jaw. This directs the force onto the strongest part of the tool.

A Comparison: Adjustable vs. Combination Wrench

| Feature | Adjustable Wrench | Combination Wrench |

| Versatility | Excellent. One tool fits many sizes. | Poor. One tool fits one size. |

| Grip Security | Fair. Prone to slipping if not used correctly. | Excellent. The box end provides a secure, non-slip grip. |

| Torque Application | Low. Not suitable for high-force tasks. | High. Designed to apply significant leverage safely. |

| Best Use Case | Low-torque situations, odd sizes, or as a backup tool. | Primary tool for breaking loose and tightening most fasteners. |

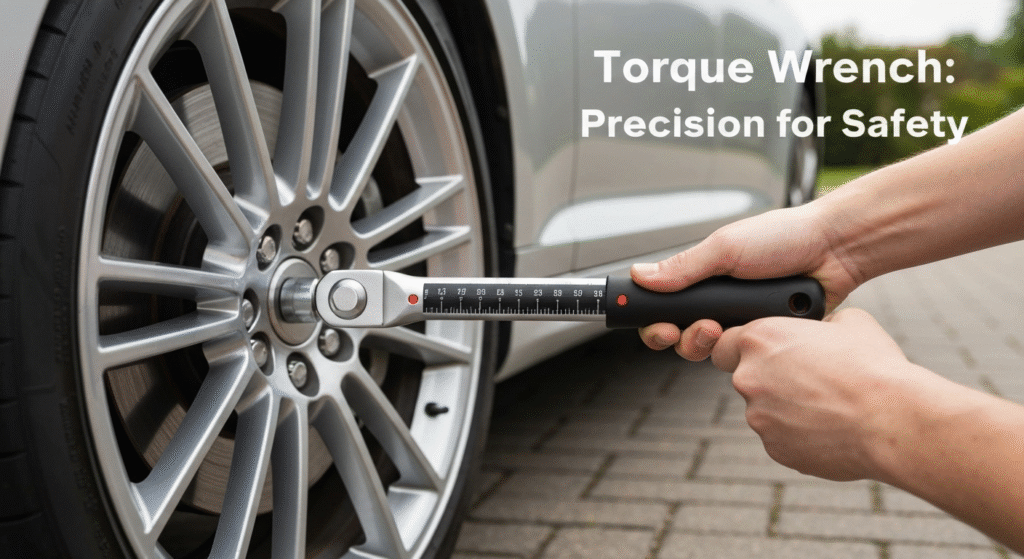

The Precision Instrument: The Torque Wrench

While other wrenches are for turning, the torque wrench is for measuring. Its only purpose is to apply a precise and specified amount of rotational force (torque) to a fastener. This is not a luxury tool; for many jobs on a modern car, it is an absolute necessity for safety and reliability.

Why Torque is Critical in Automotive Work

Many people think “tighter is better,” but that’s a dangerous misconception.

- Under-tightening: A bolt that is too loose can vibrate free over time. Imagine this happening to your wheel’s lug nuts or a critical suspension component.

- Over-tightening: A bolt that is too tight can stretch, weaken, and eventually break. It can also damage the threads of the part it’s screwed into, or warp sensitive components like engine gaskets or brake rotors.

Your car manufacturer provides exact torque specifications for nearly every bolt on your vehicle. The torque wrench is the only tool that allows you to meet these specifications. Lug nuts are the perfect example. Every car has a specific torque value for them, usually found in the owner’s manual. Applying this exact torque ensures the wheel is secure but doesn’t damage the expensive wheel hub or brake rotor.

Types of Torque Wrenches

There are a few styles, but the click-type is the most common and user-friendly for beginners.

- Click-Type: You set the desired torque value by twisting the handle and lining it up with a scale on the shaft. When you tighten the bolt and reach that value, the wrench’s internal mechanism makes an audible “click” that you can also feel in the handle.

- Beam-Type: A simpler design with a pointer that bends along a scale to show you how much torque you’re applying. They are inexpensive but can be harder to read accurately.

- Digital: These have an electronic screen that displays the torque value and will often beep or vibrate when you reach the target. They are highly accurate but more expensive.

How to Use a Click-Type Torque Wrench

Using one is simple, but it requires care.

- Look up the correct torque specification for the bolt you are tightening in your car’s repair manual.

- Twist the handle on the wrench to set it to that exact specification.

- Place the wrench on the fastener and tighten with a smooth, steady motion. Do not jerk the wrench.

- Stop immediately when you hear and feel the “click.” The click means you are done. Do not pull further.

- Crucially, always turn the handle back to its lowest setting after you are finished. Storing a click-type wrench under tension will wear out the internal spring and ruin its accuracy.

Specialty Wrenches You Might Encounter

As you tackle more jobs, you may come across fasteners that require a special tool. Here are a couple of the most common ones.

The Allen Wrench (Hex Key)

An Allen wrench is an L-shaped tool with a hexagonal tip. It’s used for bolts that have a hexagonal recess in their head, often called Allen bolts or socket head screws. In cars, these are frequently used for things like securing interior plastic panels, some brake caliper guide pins, and drain plugs on transmissions or differentials. They usually come in sets containing many different sizes.

The Oil Filter Wrench

This tool does exactly what its name implies: it helps you remove and install your engine’s oil filter. Filters are often in tight spaces and can become very tight over time, making them difficult to remove by hand. There are several styles, including wrenches that look like a large socket, plier-style wrenches with teeth for grip, and band-style wrenches that use a loop of metal to grab the filter. The best style often depends on how much access you have to the filter on your specific car.

Building Your First Wrench Set: A Practical Approach

You do not need to buy a 500-piece master mechanic’s tool set to get started. In fact, doing so can be a waste of money. A smarter approach is to start with the essentials and add tools as you need them for specific projects.

For a beginner working on a modern car, I always recommend starting with these two core sets:

- A Metric Combination Wrench Set: A quality set ranging from 8mm to 19mm will cover the vast majority of fasteners you will encounter during basic maintenance.

- A 3/8-inch Drive Socket Set: This should include a ratchet, a few extensions, and a range of metric sockets, again from about 8mm to 19mm. Make sure the set includes 6-point sockets.

With just these two sets, you can accomplish an incredible number of tasks, from changing your oil to replacing a battery to swapping out an air filter. As you decide to tackle more advanced jobs like brake work or suspension repairs, you can then invest in the specific tools needed, such as a 1/2-inch drive set or a torque wrench.

Frequently Asked Questions

What’s the difference between 6-point and 12-point sockets?

A 6-point socket has six points of contact and grips the flat sides of a bolt, providing the best possible grip and reducing the chance of stripping it. A 12-point socket has twelve points, which allows it to engage a bolt at more angles, but it grips the corners and is more likely to slip on a very tight or slightly worn bolt. For beginners, a 6-point set is the safer, more reliable choice.

Do I need both Metric and SAE (Imperial) wrenches?

It depends on your vehicle. Almost all cars built in the last 20-30 years, including those from American brands, primarily use metric fasteners. If you have a newer car, start with a metric set. You may only need a few specific SAE tools for certain parts. If you work on classic American cars, an SAE set will be essential.

How do I stop a wrench from slipping and stripping a bolt?

First, ensure you are using the correct size wrench; it should fit snugly with no wiggle room. Second, use the box end of a combination wrench or a 6-point socket whenever possible. Third, make sure the wrench is fully seated on the bolt head. Finally, pull the wrench with a smooth, steady force rather than a sudden jerk.

Is it okay to use a pipe on a wrench for more leverage?

No, you should never do this. Adding a “cheater bar” pipe to the end of a standard wrench or ratchet can apply far more force than the tool was designed to handle, causing it to break and potentially injuring you. If you need more leverage, use a tool designed for it, like a longer-handled “breaker bar.”

Conclusion

Your toolbox doesn’t have to be a place of mystery. By understanding the purpose of these fundamental wrench types—the versatile combination wrench, the efficient socket set, the precise torque wrench, and the situational adjustable wrench—you are arming yourself with powerful knowledge. Each tool is designed to make a specific job easier, safer, and more effective.

Start small, invest in a quality basic set, and build your collection as you build your skills. The confidence that comes from successfully completing your own car maintenance is immense. You can save money, learn more about the machine you depend on every day, and gain a valuable life skill. The right wrench is more than just a piece of steel; it’s the key to unlocking your potential as a capable car owner.